Part 1 – The Idea

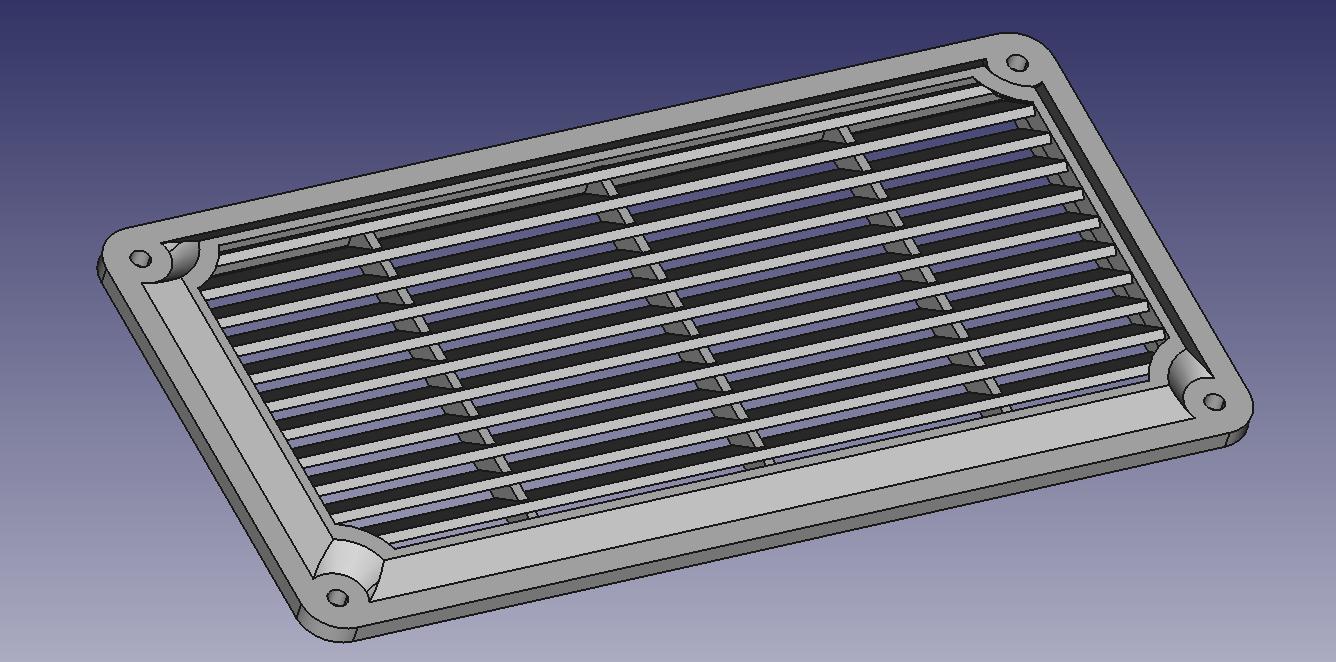

A few years ago, while I was perusing NASA tech briefs, I came across an article about how they were testing additive manufacturing to replicate parts in space, on demand. That is, instead of carrying a store of spares onboard a Mars mission to replace anything that might break or get lost, they would instead carry the raw materials in the form of feedstock for 3D printers which produce metal parts from CAD files. In fact NASA has been testing the use of additive manufacturing to produce critical (high temperature ) parts for rocket motors. This got me to thinking: Could I put together such a setup to use on a cruising sailboat? Obviously printing metal parts was a no-go from a power consumption standpoint and the shear amount of space needed for the equipment. However, my boat has many plastic parts from the trim around the opening on the mast where lines exit , deck fill caps, vents, various bits of trim, knobs, cabin light lenses, and so on. Good 3D printers can now be found for less than $500 and are able to print using a variety of plastics including PETG, and Nylon which hold up well under the intense UV of the tropical sun.

There were a number of considerations that initially came to mind for my own foray into onboard additive manufacturing:

- Which 3D printer

- Strength of the printed parts

- Power consumption. I.e. could it be run from the house batteries charged from Solar and Wind?

- Software for designing the parts

- Some kind of database for organizing the files so I can find them later.

In the coming posts I’ll explore these and other questions.

Blogging from onboard Sérénité: Back Creek, Annapolis, Maryland, United States, North America.